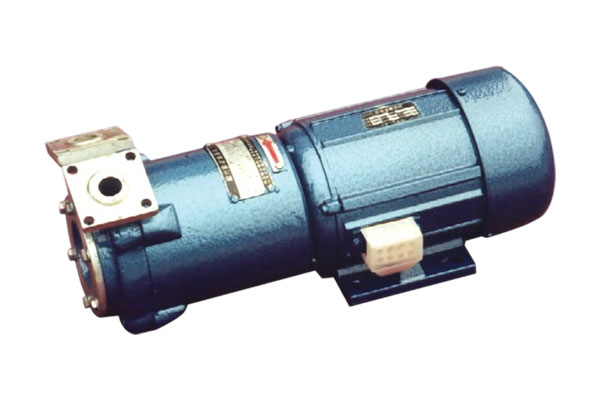

Metal Magnetic Vortex Pump

CKW Type-

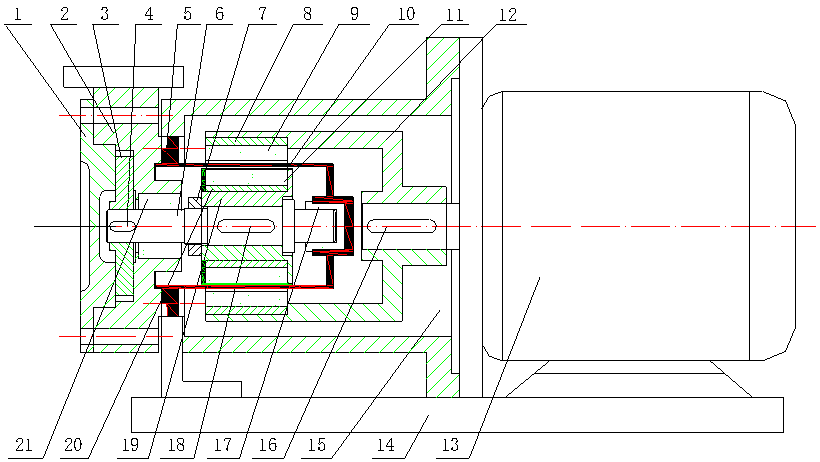

Our company has developed isolated sleeve making of CF/PEEK. After pressure test, pressure resistance of them exceeds 3MPA.

Hastelloy isolated sleeve by stretch forming eliminate the weakness of welding and improve its corrosion resistance and pressure resistance. This makes pump operating safer.

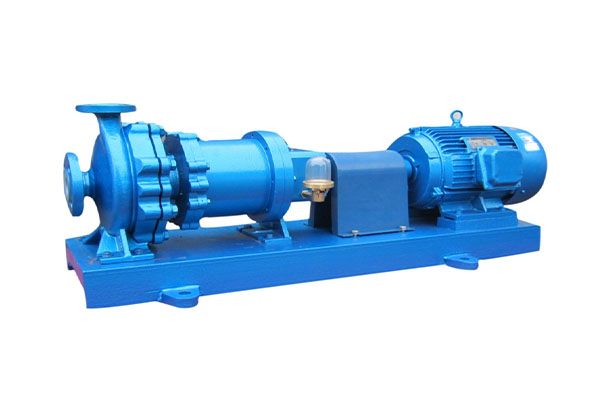

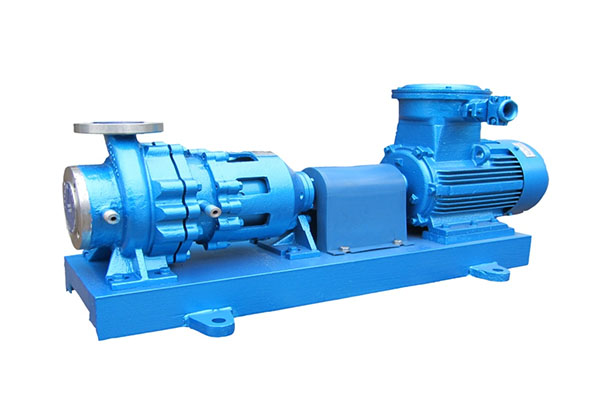

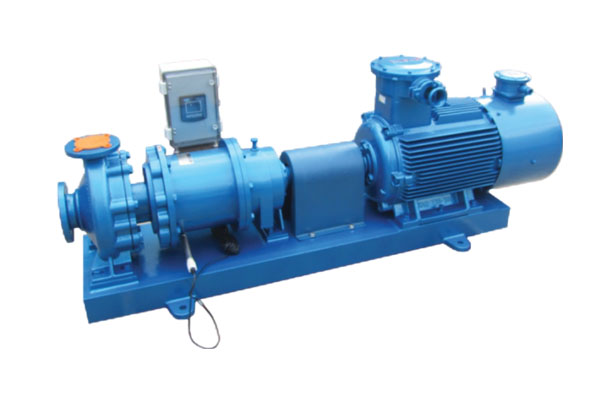

Applying with the according protection equipment, our magnetic drive centrifugal pumps have significant higher levels of safety and reliability. For our company’s metal magnetic driving centrifugal pumps, the wearing parts of sliding bearing, thrust bearing and shaft sleeve are made of tungsten carbide. We use tungsten carbide for pump’s wearing parts. Its abrasion resistance is almost same as silicon carbide and bending strength is high. This protect wearing parts from breaking while transferring medium with granule or non-loading, and avoid the leakage for the friction between inner magnetic steal and isolated sleeve.

After years of developing, testing and innovation, we have achieved our own efficient hydraulic model, and the magnetic drive centrifugal pump’s performance increases 3% to 8 %.

The metal magnetic driving centrifugal pump is a leak-free pump. In the existing magnetic driving centrifugal pump, no matter what kind of structure the magnetic driving centrifugal pump isolating has, if sleeve wears, the medium will leak directly into the atmosphere. In this situation, the unsealed magnetic driving centrifugal pump has no advantage comparing the sealed centrifugal pump. This still cause air pollution and threat safe production.

The company has five authorized invention patents, fifteen utility model patents, and six copyright works. With an integration of professional design, research, manufacture and marketing, we have a leading international position in the field of magnetic drive pumps.

Choose us for an excellent experience in the product with the latest technology.

-

Model

Flow

Lift

Speed

Shaft Power

Motor Power

Efficiency

Impeller Diameter mm

Remark

Type

(m3/h)

(m)

(r/min)

(kw)

(kw)

%

Impeller Diameter

Remark

Flow Rate

Head

Rotational Speed

Shaft

Motor Power

Efficiency

Power

CKW-20

0.36

28

2900

0.196

0.55

14

65

0.7

20

0.178

22

0.9

15

0.175

21

CKW-30

1.73

52

2900

1.066

1.5

23

85

2.88

30

0.735

32

3.6

20

0.632

31

CKW-40

3.6

60

2900

2.36

4

25

95

5.4

40

1.73

34

6.48

26

1.35

35

CKW-75

1.73

115

2900

2.36

4

23

115

2.88

75

1.96

30

3.6

53

1.73

31.5

CKW-105

2.05

130

2900

2.86

3

25.5

130

2.4

110

2.46

29

2.88

85

2.11

31.5

CKW-18

0.2

18

2900

0.08

0.18

12

75

Non-Metal

CKW-26Z

1.44

26

1400

0.81

1.5

26

80

CKW-65

0.72

65

2900

0.85

1.5

15

105

-