Explore Metal Magnetic Centrifugal Pumps: Innovation and Application of Leak-Free Pump Technology

Release Time : 2024-11-06

In the modern industrial field, metal magnetic centrifugal pumps have received widespread attention and favor due to their unique leak-free and pollution-free characteristics. This article will discuss in detail the working principle, structural characteristics, application fields, advantages and disadvantages of metal magnetic centrifugal pumps to provide readers with a comprehensive understanding.

Working principle

The working principle of metal magnetic centrifugal pumps is based on the principle of magnetism. The power source is generally an electric motor, which drives the external permanent magnet (active magnet) to rotate. The magnetic field generated by the active magnet is transmitted to the internal permanent magnet (driven magnet) through an isolation sleeve (made of non-magnetic material). Due to the effect of the magnetic field, the driven magnet drives the impeller in the pump to rotate synchronously, thereby realizing the delivery of liquid. During the whole process, there is no mechanical connection between the pump shaft and the motor shaft, so there is no need to use a sealing device, which fundamentally solves the leakage problem caused by damage to the seal of the traditional centrifugal pump.

Structural features

The metal magnetic centrifugal pump is mainly composed of a motor, a magnetic coupling, a pump body, an impeller, and an isolation sleeve. Among them, the magnetic coupling is the key component to achieve contactless torque transmission, and its performance directly affects the working efficiency and service life of the magnetic drive centrifugal pump. The magnetic coupling is usually composed of an active magnet, a driven magnet and an isolation sleeve. The active magnet and the driven magnet interact through the magnetic field to achieve torque transmission. The isolation sleeve is made of non-magnetic material and is used to isolate the motor and the liquid in the pump body to ensure the purity of the pump body.

The design of the metal magnetic centrifugal pump is usually very compact, easy to install, and suitable for various complex environments. The pump body is usually made of metal material with certain strength and corrosion resistance. The rotor is the rotating part inside the pump body and is made of magnetic material. The magnetic coupling realizes contactless transmission of power through the action of the magnetic field, thereby avoiding the leakage problem of traditional pumps.

Application field

Metal magnetic centrifugal pumps have been widely used in many fields due to their leakage-free and pollution-free characteristics. In the chemical and petroleum industries, magnetic-driven centrifugal pumps can be used to transport various corrosive, flammable, explosive, toxic and harmful liquids; in the pharmaceutical and electroplating industries, magnetic-driven centrifugal pumps can ensure the purity and pollution-free nature of the transported liquids; in the field of environmental protection, magnetic-driven centrifugal pumps can be used to treat various wastewaters and waste liquids. In addition, magnetic centrifugal pumps are also widely used in acid and alkali production, smelting, rare earths, pesticides, dyes, papermaking, film photography, scientific research institutions, and defense industries.

Advantages and Disadvantages

The advantages of metal magnetic centrifugal pumps are mainly reflected in the following aspects:

No leakage, no pollution: ensure the purity and safety of the transported liquid.

No need to use sealing devices: reduce maintenance costs and failure rates.

Compact structure and easy installation: suitable for various complex environments.

However, metal magnetic centrifugal pumps also have some disadvantages:

Relatively low efficiency: due to the effect of the magnetic field, there is a certain amount of energy loss inside the pump body.

High manufacturing cost: The manufacturing cost of the magnetic coupling is high, resulting in a relatively high price for the entire pump.

High requirements for impurities and particles in the liquid: Once the liquid contains more impurities and particles, it is easy to cause damage or failure of the magnetic coupling.

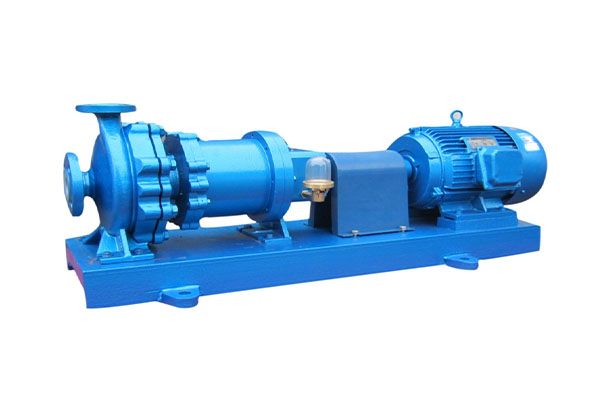

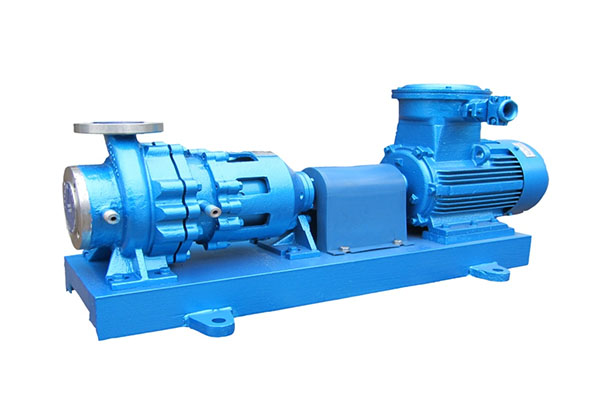

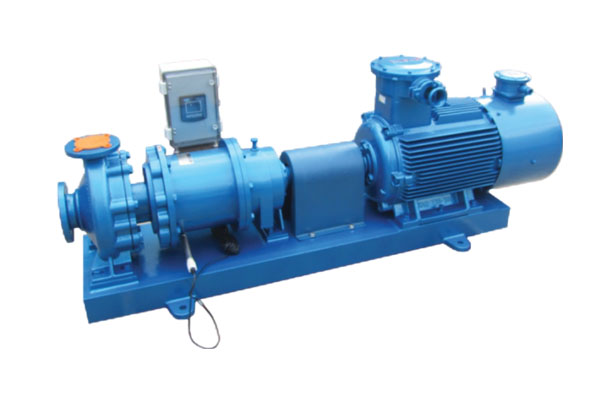

Example analysis

Take the IMC type metal magnetic drive centrifugal pump as an example. The pump adopts a dense magnetic push-pull magnetic circuit structure to achieve contactless transmission of torque, cancel the shaft seal of the traditional mechanical seal pump, and replace the dynamic seal with a static seal to achieve a fully sealed, leak-free conveying medium. IMC type metal magnetic drive centrifugal pump is widely used in petroleum, chemical, pharmaceutical, fertilizer, smelting, electroplating, food, film and television printing, water treatment and other industries. It is an ideal equipment for conveying flammable, explosive, volatile, toxic, rare and precious liquids and various corrosive liquids.

As a new type of leak-free and pollution-free pump product, the metal magnetic centrifugal pump has broad application prospects in the modern industrial field. Its unique working principle and structural characteristics make it perform well in many fields. Despite some shortcomings, with the continuous emergence of new materials, new processes and new technologies, the performance of metal magnetic centrifugal pumps will continue to improve and their application scope will be further expanded.

Working principle

The working principle of metal magnetic centrifugal pumps is based on the principle of magnetism. The power source is generally an electric motor, which drives the external permanent magnet (active magnet) to rotate. The magnetic field generated by the active magnet is transmitted to the internal permanent magnet (driven magnet) through an isolation sleeve (made of non-magnetic material). Due to the effect of the magnetic field, the driven magnet drives the impeller in the pump to rotate synchronously, thereby realizing the delivery of liquid. During the whole process, there is no mechanical connection between the pump shaft and the motor shaft, so there is no need to use a sealing device, which fundamentally solves the leakage problem caused by damage to the seal of the traditional centrifugal pump.

Structural features

The metal magnetic centrifugal pump is mainly composed of a motor, a magnetic coupling, a pump body, an impeller, and an isolation sleeve. Among them, the magnetic coupling is the key component to achieve contactless torque transmission, and its performance directly affects the working efficiency and service life of the magnetic drive centrifugal pump. The magnetic coupling is usually composed of an active magnet, a driven magnet and an isolation sleeve. The active magnet and the driven magnet interact through the magnetic field to achieve torque transmission. The isolation sleeve is made of non-magnetic material and is used to isolate the motor and the liquid in the pump body to ensure the purity of the pump body.

The design of the metal magnetic centrifugal pump is usually very compact, easy to install, and suitable for various complex environments. The pump body is usually made of metal material with certain strength and corrosion resistance. The rotor is the rotating part inside the pump body and is made of magnetic material. The magnetic coupling realizes contactless transmission of power through the action of the magnetic field, thereby avoiding the leakage problem of traditional pumps.

Application field

Metal magnetic centrifugal pumps have been widely used in many fields due to their leakage-free and pollution-free characteristics. In the chemical and petroleum industries, magnetic-driven centrifugal pumps can be used to transport various corrosive, flammable, explosive, toxic and harmful liquids; in the pharmaceutical and electroplating industries, magnetic-driven centrifugal pumps can ensure the purity and pollution-free nature of the transported liquids; in the field of environmental protection, magnetic-driven centrifugal pumps can be used to treat various wastewaters and waste liquids. In addition, magnetic centrifugal pumps are also widely used in acid and alkali production, smelting, rare earths, pesticides, dyes, papermaking, film photography, scientific research institutions, and defense industries.

Advantages and Disadvantages

The advantages of metal magnetic centrifugal pumps are mainly reflected in the following aspects:

No leakage, no pollution: ensure the purity and safety of the transported liquid.

No need to use sealing devices: reduce maintenance costs and failure rates.

Compact structure and easy installation: suitable for various complex environments.

However, metal magnetic centrifugal pumps also have some disadvantages:

Relatively low efficiency: due to the effect of the magnetic field, there is a certain amount of energy loss inside the pump body.

High manufacturing cost: The manufacturing cost of the magnetic coupling is high, resulting in a relatively high price for the entire pump.

High requirements for impurities and particles in the liquid: Once the liquid contains more impurities and particles, it is easy to cause damage or failure of the magnetic coupling.

Example analysis

Take the IMC type metal magnetic drive centrifugal pump as an example. The pump adopts a dense magnetic push-pull magnetic circuit structure to achieve contactless transmission of torque, cancel the shaft seal of the traditional mechanical seal pump, and replace the dynamic seal with a static seal to achieve a fully sealed, leak-free conveying medium. IMC type metal magnetic drive centrifugal pump is widely used in petroleum, chemical, pharmaceutical, fertilizer, smelting, electroplating, food, film and television printing, water treatment and other industries. It is an ideal equipment for conveying flammable, explosive, volatile, toxic, rare and precious liquids and various corrosive liquids.

As a new type of leak-free and pollution-free pump product, the metal magnetic centrifugal pump has broad application prospects in the modern industrial field. Its unique working principle and structural characteristics make it perform well in many fields. Despite some shortcomings, with the continuous emergence of new materials, new processes and new technologies, the performance of metal magnetic centrifugal pumps will continue to improve and their application scope will be further expanded.